| This example requires that we use the "Start from Primary Package" window instead of using the "Fill Container" window to load a container with floor-loaded boxes. This is because we will be using the Advanced Input Options window. Hence, the first step is to load a new window starting from Primary Package dimensions. |

|

| Once the window appears, we will enter the primary dimensions, weight, case constraints and the limitations of the load. Since we will not use pallets, we enter zero for the pallet dimensions and the internal container dimensions as the maximum load dimensions. In this case, we copied the dimensions that are available from the Container list in the second tab of the Standard Cases and Pallets window. |

|

| After entering the input data in the appropriate window, we're ready to commence the calculations. Please note that in this case, we didn't enter the case count because we will be running different scenarios with varying case counts. To run these scenarios, we open the Advanced Input Options window from the Tools menu. |

|

| From the Advanced Input Options window, we will select to vary the Case Count between 11 units per box (a smaller number is not practical because of the excessive shipped carton per pack) and 51 (we do not pick a larger count to not make the boxes too heavy). We pick "achieve a value as high as possible for Primary Packages per Pallet" because PP/Pallet is our best indication of filling efficiency. Since all the case counts are evaluated, there is no need to change the number of iterations. Finally, we pick to show all the results (in case we see another value we prefer) and click on the "OK" button. |

|

| After calculating all the possible options (it should take a while), Quick Pallet Maker produces the possible floor-loaded box configurations (182 boxes and 546 container loads). Note that the calculation process can be stopped by pressing "Escape" on Windows machines or "Command+Period" on a Mac. |

|

| Although the application had already ordered the container loads by primary packages per pallet in decreasing order, we repeat the exercise for educational purposes. After selecting "Power Sort..." from the Tools menu, we see a small window in which we can select the ordering criteria. |

|

| Since they had already been ordered, the result doesn't change much, as can be seen in the screenshot at right. |

|

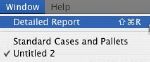

| Given that we have already selected the best result for fitting packages into containers independently of the case count but with some consideration towards the people who load the boxes into the containers (i.e. not exceeding the weight they can carry), we can select "Detailed Report" from the Window menu as in the screenshot at right. |

|

| The final report can then be saved or exported in a graphics format to send to the packers and unpackers. |

|