| The first step is to run QPM and open a new Container Fill window by choosing the appropriate command from the File menu. A new window will appear as in the screenshot at right. |

|

Since we will be introducing the case dimensions manually, we select "Case Properties" from the pull-down menu at the top-left corner of the Container Fill window. The case specifications are the following:

- 500 red boxes that measure 485x335x220mm and weigh 13.07kg

- 250 blue boxes that measure 485x335x220mm and weigh 13.07kg

- 300 green boxes that measure 340x225x260mm and weigh 11.34kg

- 500 black boxes that measure 485x335x220mm and weigh 13.07kg

|

|

| Every time we add a box (by clicking on the "Add Box" button), we change the color of the box by clicking on the box drawing with the right mouse button (Windows and multi-button mice on Mac OSX) or ctrl+click (one-button Mac). |

|

| This action reveals a color palette that will change depending on your operating system. From this palette, we can select a color. |

|

| Once all boxes have been added, we change the container type to 45' container. The container restrictions change automatically. |

|

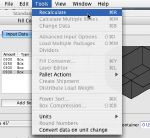

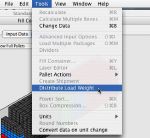

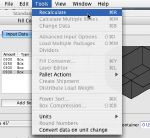

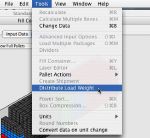

| With the data in place, we select "Recalculate" from the Tools menu or click on the second tab in the window. |

|

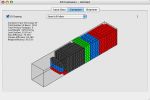

| After a certain period of time, Quick Pallet Maker will show the resulting container load. If we check the drawing at right, we will notice that the container has been optimized in such a way that the boxes are placed against the back of the container. This is excellent if we would like to add more items to the container. However, the client has mentioned that she will only ship those boxes (and none other). Hence, the resulting load needs to be optimized for road transport. In its current state, too much pressure is being applied to the back trailer wheels. |

|

| The first alternative that is available in QPM is to simply center the load. This method calculates the load center of gravity and places it in such a way that it will exert the most downward force in the container center. To do this, we select "Distribute Load Weight" from the Tools menu. |

|

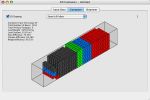

| The resulting container will have the same load configuration but centered. This load is good for transport but the client is still not satisfied because the boxes could topple if the truck hits potholes or other bumps on the road. |

|

| Hence, we go back to the "Input Data" tab and change the maximum load height to a lower value. In this case, we will use 2000mm (a guess) instead of the previous 2600mm. |

|

| After selecting "Recalculate" again, we can see that the load is better distributed on the floor of the container. However, we can still check a lower allowable height. |

|

| We go back to the input tab and choose 1800mm instead. |

|

| After recalculating, we can see that we have obtained a very well distributed load that uses up most of the container floor (Area Efficiency > 98%). Note that if we would have used a lower height, we would have needed another container. |

|